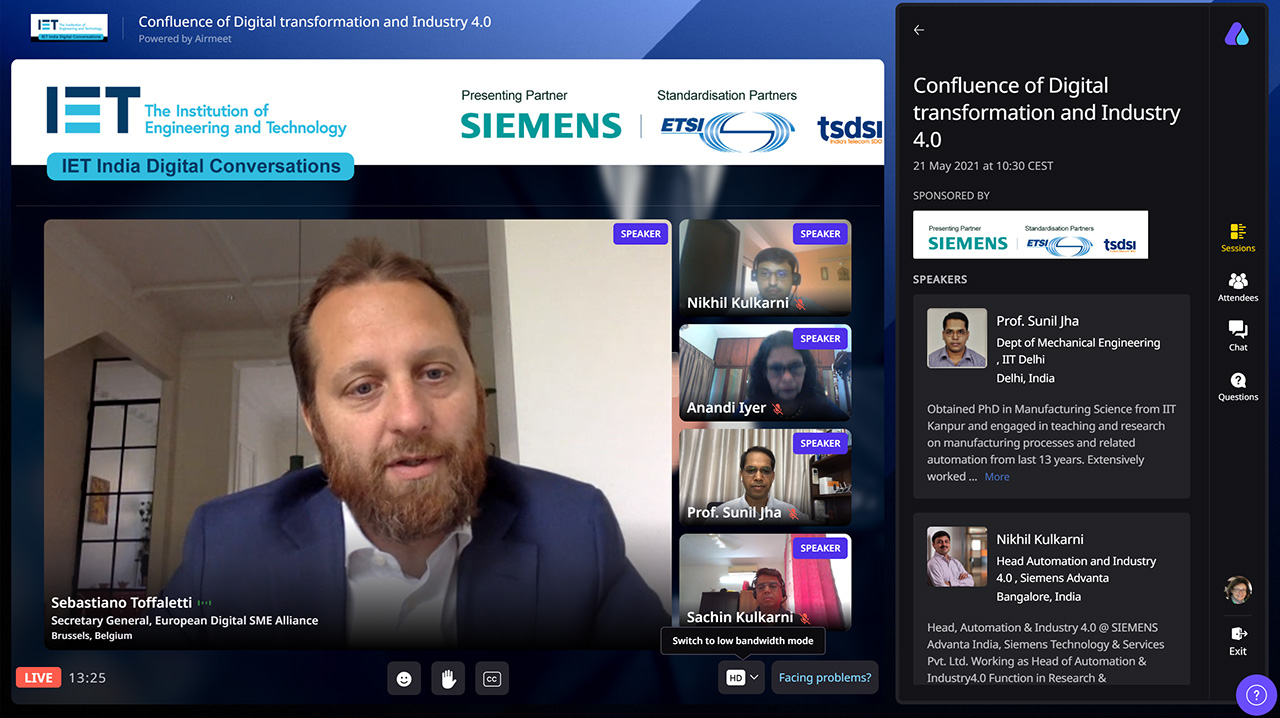

IET INDIA DIGITAL CONVERSATION ON DIGITAL TRANSFORMATION AND INDUSTRY 4.0, HELD ON MAY 21, 2021

In this IET India Digital Conversation held on May 21, 2021, digital experts were brought together to engage in a workshop discussing the need to derive a holistic view of the digital journey through an end-to-end value-chain. The session was held by IET India Digital Conversations, in association with ETSI and TSDSI (Telecommunications Standards Development Society, India) as Standardisation Partners.

The online session involved more than 150 attendees participating from organisations including Siemens, L&T, Jindal Stainless, Amara Raja Batteries, Mercedes Benz R&D India, Harman Connected Service, AECOM, HAL, Godrej, Adani, EY, Deloitte, Capgemini, AT&T, Reliance Jio, Festo India, Dell, TCS, Mathworks and many more. This was a global event, with attendees from across India, joined by delegates from UAE, Dubai, Sri Lanka, Switzerland, France, Belgium and the UK.

The online session involved more than 150 attendees participating from organisations including Siemens, L&T, Jindal Stainless, Amara Raja Batteries, Mercedes Benz R&D India, Harman Connected Service, AECOM, HAL, Godrej, Adani, EY, Deloitte, Capgemini, AT&T, Reliance Jio, Festo India, Dell, TCS, Mathworks and many more. This was a global event, with attendees from across India, joined by delegates from UAE, Dubai, Sri Lanka, Switzerland, France, Belgium and the UK.

The session was summarised by the idea that there would only be two types of companies in the future - ones that are digital and ones that will become digital. The conversation focused broadly on the opportunities and challenges facing countries undergoing digital transformation and more specifically looking at India, which is one of the largest and fastest growing markets for digital consumers after China. By 2025, core digital sectors such as IT & BPM, digital communication services and electronics manufacturing could double their GDP level to around $450 billion.

Digital standardization was highlighted as a major factor aiding digital transformation. oneM2M, a standard for machine to machine communication that was developed in collaboration between Europe and India, was cited as an example of this. A specific example was highlighted, where elevator manufacturers developed, in collaboration with ETSI and TSDSI, a oneM2M specification for ‘Smart Lifts’. Thanks to this standard there is a consortium of SME’s that have developed their own platform to get IoT into existing analog lifts, with the plan to have this deployed into 40,000 lifts by the end of 2021. This is a clear example of how standardisation can help drive forward the digitalisation of analog products.

The opportunities for transformation in India are enormous. New sectors that are undergoing digital transformation include agriculture, education, energy, healthcare, logistics, retail as well as government services and labour. This digitisation could each create up to 150 billion of incremental economic value by 2025. The productivity unlocked by the digital economy could create large numbers of jobs if re-skilling is a prime focus.

The key to a faster pace of innovation that generates value is ‘sustainable digitalisation.’ The core objective of digitalisation should be the reduction of waste in the manufacturing lifecycle which would in turn lead to speed, flexibility, quality, efficiency and allow for new emerging business models to exist and operate.

Digitalisation and Industry 4.0 is based on 4 main tenets: pragmatic and directional RoI, monetisation of business models, socio-economic and environmental impact and keeping humans at the centre to allow for creativity and better innovation.

Before embarking on a digitalisation transformation, a digital maturity assessment is required in order to fully understand where the digital journey must start from - and to identify which projects should be focused on. It’s also critically important to have a clear roadmap for digitalisation. Technology is all about experimentation and management is about execution. Organisations should be willing to adapt, fail and emerge.

View the full recording of the Digital Conversation on Digital Transformation and Industry 4.0 – 21 May 2021.